TSC Signs – Your Specialists in Traffic & Construction Signs

In the next of our series of blogs, TSC Signs explores Flatbed Printing provides a full guide and analysis, including the process, advantages and limitations. The team at TSC Signs has over 30 years of experience in producing traffic signs and can help and guide customers where required.

Definition of Flatbed Printing

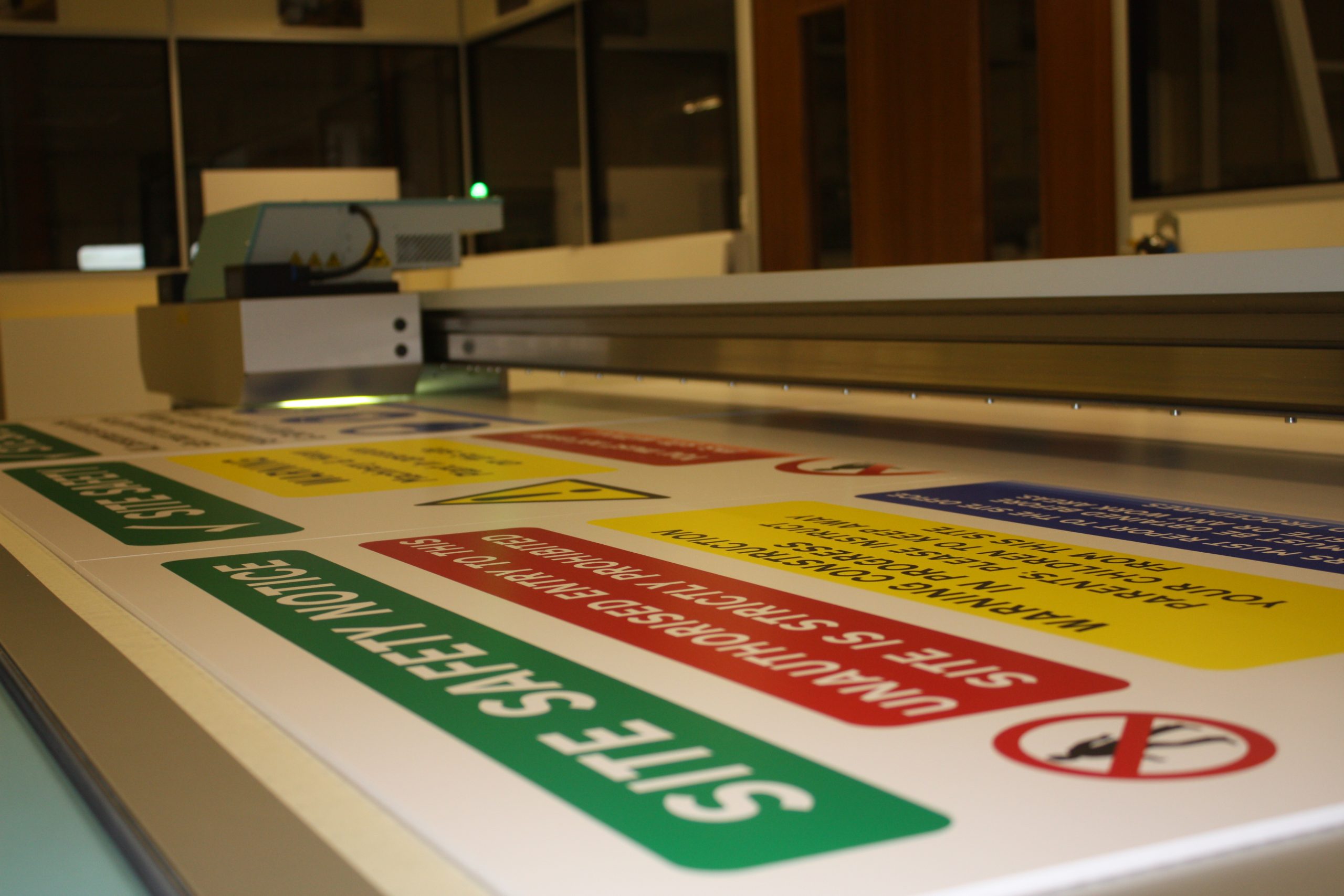

Flatbed printing is a type of digital printing technology that allows for high-quality printing on a variety of materials such as paper, plastic, glass, and metal. This printing method involves placing the material on a flat surface and printing onto it using a large flatbed printer.

The Process of Flatbed Printing

The process of flatbed printing begins with the creation of a digital file that contains the image or design to be printed. This file is then sent to the flatbed printer, which uses specialized inkjet technology to print the design onto the material. The printer uses a series of nozzles to spray tiny droplets of ink onto the surface of the material, creating the desired image or design.

The Advantages of Flatbed Printing

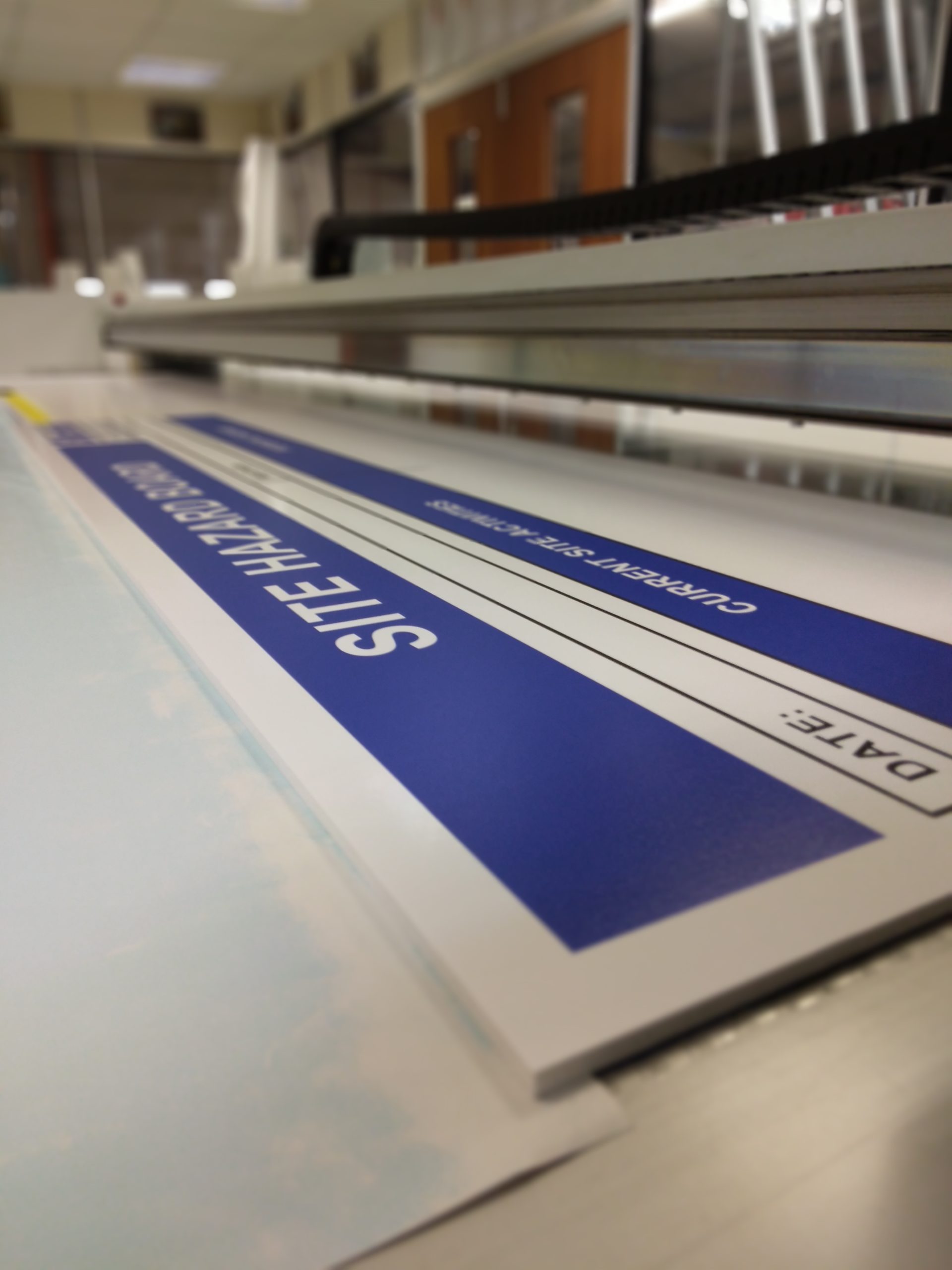

One of the primary advantages of flatbed printing is its versatility. This printing method can be used to print on a wide range of materials, including rigid and flexible substrates, such as foam board, PVC, acrylic, and textiles. This makes flatbed printing an excellent choice for a variety of applications, including advertising, packaging, signage, and product labeling.

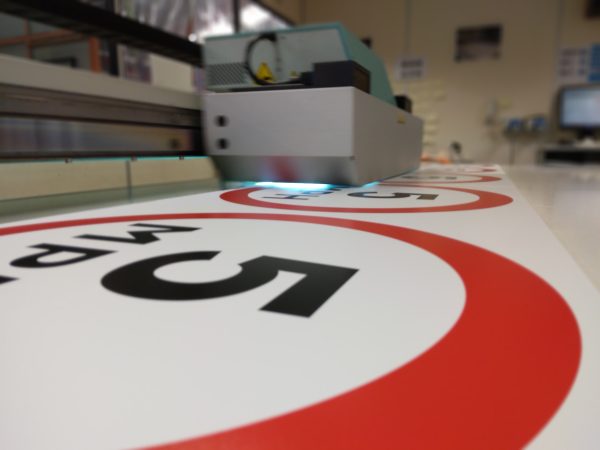

Another advantage of flatbed printing is its ability to produce high-quality, detailed prints. This is due to the advanced inkjet technology used by flatbed printers, which allows for precise control over the printing process. Flatbed printers are capable of producing prints with resolutions of up to 1440 x 1440 dpi, resulting in sharp, vibrant images that are perfect for high-end applications.

Flatbed printing is also a fast and efficient printing method. With the ability to print multiple copies of a design quickly and easily, flatbed printing is an excellent choice for large-scale printing projects. This printing method is particularly well-suited for short-run printing, where smaller quantities of prints are required.

Limitations of Flatbed Printing

One of the limitations of flatbed printing is its cost. Flatbed printers are expensive to purchase and maintain, which can make this printing method less cost-effective for smaller printing projects. However, for larger printing projects where quality and speed are essential, the cost of flatbed printing can be more reasonable.

Conclusion

In conclusion, flatbed printing is a versatile, high-quality printing method that is suitable for a wide range of applications. Its ability to print on a variety of materials, produce high-quality prints with precise details, and fast and efficient printing make it an excellent choice for large-scale printing projects. While the cost of flatbed printing may be higher than other printing methods, its benefits make it a worthwhile investment for those in need of high-quality printing services.